COMMODITY INSPECTION

PRE-SHIPMENT INSPECTIONS (PSI)

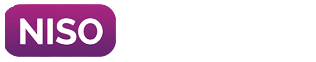

TECHNICAL INSPECTIONS

The commodity shall be inspected before shipment either at the premises of the supplier and/or at the port of loading and/or port of discharge. The inspection shall seek to ensure strict conformity of the commodity with the agreed-upon specifications.

Our services are always adapted to our client’s needs and include :

- Inspection and acceptance of ship holds, hatch covers

- speeding uploading and/or discharging operations

- supervision throughout loading /discharging

- conducting neutral analysis

- check of packing and marking

- check of bag weight

- damage assessment, if any

- photographic reporting

- Daily reporting of events

- Certification of quality, quantity& condition

- Establishment of in taken /outturn weight by means of the draft survey.

- sampling during entire loading and/or discharging operations and preparation of contractual samples

pre-shipment inspection services are designed to protect the interests of buyers in their international purchasing programs. The intervention is an essential part of an international transaction where documented proof of quality and quantity are a requirement of the payment terms.

- verification of raw or semi-manufactured materials

- sampling and analysis

- staged production inspection

- determination of quantity

- labeling and documentation control

- witnessing in - house tests

- finished product inspection

- packing and marking inspection

- supervision of stuffing into containers

- photographic reporting

- complete final reporting

Also (NISO) have well trained and qualified superintendents and experienced Office -Staff are ready to carry out your superintending orders and documentary work as well as to assist you in storage, agency, forwarding, and eventual informative matter. Amongst our staff, you will find a qualified FOSFA and GAFTA arbitrator, also a member of FOSFA’S appeal Panel.

(NISO) is a superintendent Member of FOSFA. INTERNATIONAL LONDON The Office well acquainted through his surveyors of establishing a complete ISM. System for all types of vessels including the particulars of the system. We hope you will accept our invitation to be one of our major clients.

Scope of work which may incorporate any or all of the following beneath listed services.

VISUAL INSPECTION

Visual inspection of the material /equipment for quality workmanship, defects and cleanliness of work

COMPLIANCE WITH SPECIFICATIONS AND DRAWINGS

Welding procedures, welder qualification, coating , rating, material certificates ,shop procedures , etc. Shall be verified for compliance with specifications, drawings and standard industry practices.

WITNESSING

Witness (non-)destructive and chemical testing of materials, mechanical run test, functional test, vibration test, noise emission test, electrical performance test, etc.

INSPECTION CERTIFICATE

Issue an inspection certificate immediately after all inspections are completed stating that the equipment or material is in strict accordance with the requirements of the purchase order

DIMENSIONAL CHECKS

Carry out checks to ensure that material/equipment is dimensionally in accordance which approved drawings

PACKING AND MARKING INSPECTION REPORTING

Submit detailed reports of all services performed inspection activities for each purchase order will be reported separately